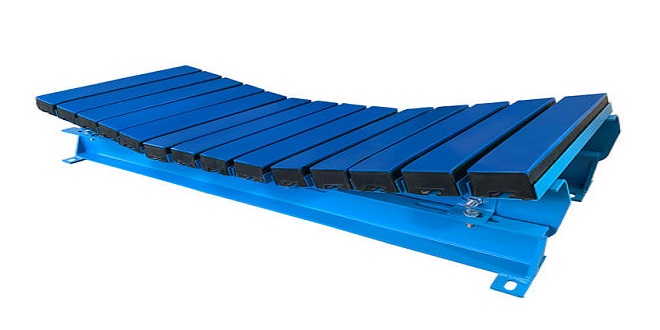

Why choose BAI-OTT Impact bed?

BAI-OTT, a professional manufacturer and supplier of buffer bed and buffer strips, receives many customer enquiries every day. BAI-OTT customers include suppliers and dealers. The buffer strip is often contacted by new customers who have no idea about its quality, working conditions, and impact on the buffer bed’s use. They also don’t know much about the effect of being the core component in the buffer mattress on its use. BAI-OTT must conduct an in-depth analysis of the buffer bed’s impact on it. This will help customers better understand it.

Before we analyze the buffer strip, let’s first discuss the German and German industries, and the concept and services of BAIOTT rubber company. The world is blessed with the German nation and German industry. We will be amazed at the long-term contacts and exchanges among Germans. The things they do are unlike any domestic enterprise. There are very few large businesses in Germany. They are made up of small and medium-sized businesses. Each of their industrial owners only make simple products. In the case of a stapler manufacturer, our four-generation family produces a single type of stapler. However, they continue to research and analyze new products in order to improve and be more durable. These manufacturers are the ones that focus on one product and make it exceptional. They also make German quality international, which is German, German industry. They have made products that no other country can produce. This makes German products high-value and allows them to spend more on R & D, innovation, and the production of better products.

They are strong in industry protection and respect science and knowledge. Their competition in the German industry is friendly. The competition will not cause it to lower the quality or requirements of its products. This is German industry and German corporate culture. BAI-OTT has worked for many years with German companies and is heavily influenced by German industrial culture. BAI-OTT will always be focused on its products. BAI-OTT believes in taking small steps to ensure that its products do a great job.

BAI-OTT won’t lower the quality or services of its products for short-term interest, because it believes that a high-quality product could win the market.

BAI-OTT also strives to influence all business partners who contact and collaborate with us. This allows them to see problems from customers’ perspectives and solve them for their benefit. Our dealers and traders all agree that the biggest challenge is price. While price is the only way to gain a competitive advantage, they overlook the fact that many factors affect the price of buffer strips. These include the customer’s needs and the quality of some buffer strip producers. The buffer strip is composed mainly of three components: a wear-resistant layer and a high elastic rubber. They are currently strongly bonded by thermal vulcanization technology. The following factors can affect the quality and price of the buffer strips:

Bonding technology

Market: There are many Chinese buffer strip manufacturers whose prices are very high. This is due to the fact that they don’t have hot vulcanization bonding technology. They can ensure strong bonding through high-temperature and very high-pressure vulcanization. Many times, they undergo unqualified cold-vulcanization bonding procedures.

Consequences

Wear resistant layer

(1) Material selection problem

Market: The Germans have experienced many wear-resistant selections including polyurethane and PU, but their performance has been poor. They finally chose ultra-high molecular-weight plate. Some buffer strip producers selected high-density Polyethylene as the wear-resistant layer to lower costs.

The buffer strip’s surface is extremely wear-resistant due to poor selection or poor quality. The conveyor belt’s service life was cut and wear was increased. Because they didn’t have hot vulcanization bonding technology, some manufacturers used other materials to improve their bonding strength. However, they ignored the protection of the conveyor belt. Baiott selection: baiott chooses ultra-high molecularweight polyethylene sheet with a molecular mass of not less than 5,000,000 (which can be certified and tested by a third party).

(2) Super elevation slab selection

Market: Many buffer strip suppliers won’t consider customers’ needs when designing and thicknessing their products.

Consequences of this: The buffer strip selected is not suitable for customers’ actual use, which results in rapid wear and replacement of the buffer strips, as well as increasing customer maintenance and use costs.

Selection by Baiott: Baiott rubber is a German company that has extensive experience in buffer bed design and application. They can also design and select special designs based on the specific operating conditions of the customers. Baiott has created a database that allows for the reserve design of different impact forces using mechanical analysis.

High elastic rubber

Market: To replace natural rubber of good quality with better quality, domestic buffer strip producers often opt for low-quality rubber over vulcanized tread rubber or recycled rubber with poorer quality. These rubbers are available in the market at a mere tens of thousands of yuan per tonne.

The rubber is not elastic and can even reach shore at 75-80 degrees. Rubbers that age quickly under these conditions have poor impact resistance and some rubbers may even deteriorate rapidly. They can be smashed quickly, and the buffer strip does not provide any cushioning effect.

Baiott rubber – Baiott insists on high-quality products one step at a while and chooses high-quality natural rubber (current market price is approximately 31000 tons), high elasticity, and impact resistant rubber. Some buffer strips can be used for up to a year. The buffer strips from baiott, however, can last between 1-2 years depending on how they are used.

Connect structure

Market: Customers who use the buffer bed gradually realized that the flat-mouth aluminum alloy bolt on the buffer strip can cause problems with strip channeling and raise their maintenance costs. Some manufacturers opt for the aluminum alloy structure due to its replacement cost. They have not explicitly told customers that the state prohibits the use of the aluminum alloy structure and they did not inform customers about the new design in the market.

Consequences: The channeling of bars partially causes safety hazards and increases the maintenance cost.

Selection of Baiott Baiott primarily uses galvanized steel structures connections. Each buffer strip is fitted with four anti-loosening self-locking bolts that ensure its quality.

Price of flame retardant buffer strips

Market: Many buffer strip producers often act irresponsibly towards their customers. Underground use requires that customers meet flame retardant and antistatic requirements. They choose to use ordinary buffer strips underground in order to save money and get short-term savings. This poses a great safety risk for customers.

Consequences: Customers have been exposed to potential dangers from their irresponsible attitudes and lack of awareness.

Baiott has chosen the only buffer strip R & D laboratory and inspection lab in China. Baiott rubber is able to provide third-party inspection by the National Center for Quality Supervision and Inspection of Coal Mine Support Equipment, but the factory control is more stringent. Every batch, each incoming material and every finished product is subject to rigorous inspection. Customers can check by performing a “simple inspection”, which allows them to determine if the product has flame retardant or anti-static properties.

Standard for Executives

Market: Many manufacturers mimic the production of buffer strips based on their appearance. There are no standards for raw materials or properties that can be used for reference or implemented, which results in poor product quality.

Consequences for both dealers and end-users: This has greatly increased the cost to customers (for end customers it could cause shutdowns or belt tearing and for dealers it may lose trust and cooperation with future end customers).

Selection of Baiott buffers: Most buffer strips from Baiott are supplied to Germany. However, some buffer strips are exported to Europe. These buffer strips are stricter than European standards. The factory also has strict production monitoring systems to ensure that every batch of buffer strips meets export requirements.

Unsufficient awareness about buffer strip quality

Market: Many traders and dealers reduce their costs blindly without considering quality and quality. This can lead to the following: The buffer bed is not a good buffer, but it still increases the maintenance cost for their conveyor belts, and will also increase the maintenance costs of customers.

Baiott Choice: Baiott rubber insists on quality as the primary demand of customers. It follows its own ideas and standards step by step and provides customers with products that they actually need. Baiott also considers long-term problems from the customer’s perspective. Baiott rubber is a scientific research rubber company. Baiott is always willing to help solve problems.

Baiott provides buffer bed and buffer strips concepts, as well as professional buffer-bed design and analysis engineers, professional design software developers, professional buffer strip R & E engineers, professional buffer block inspection laboratory, factory automation, European production and processing management modes. Baiaott is dedicated to ensuring quality in every aspect of its products.

Baiott provides first-class security and service to traders and dealers in the region.