Details About Shear Knife Manufacturers

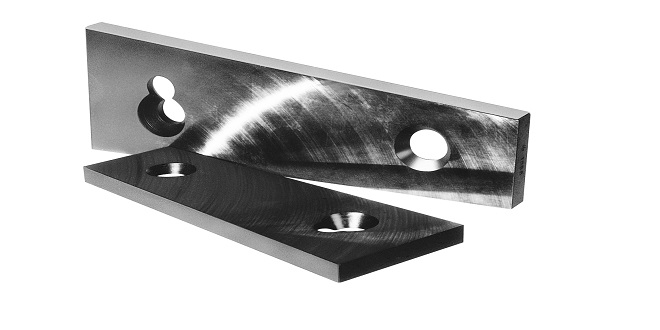

A shear knife is a type blade used to cut straight edges on blanks of plate in the metal processing industry. Two parts make up a shear knife: a moving upper blade and a fixed lower blade. They can also be made from a variety materials. Flying shear knives can be used to cut steel pipe, iron plates, and paper rolls. There are three types: disk-style, disk-style and shear-style.

Tyzack Machine Knives

Tyzack Machine Knives is looking for highly-skilled people to join their Sheffield, UK, factory. Since 2001, the company produces steel mill blades as well as hardened slideways. The current staff includes three directors and one secretary. It also provides high-quality engineering services for its customers.

Detroit Edge Tool Company

The material of the blade determines the quality of shear knives. American-made steel is the best choice for a high quality blade. Detroit Edge Tool Company is a great place to buy a high-quality shear knife. This fifth-generation family-owned business produces high-quality industrial blades. Blades manufactured by the company can handle materials up to 1,000 tonnes of shear force.

Cincinnati shear blades

You’ve found the right place if your machine needs a new set Cincinnati shear blades. The blades of Cincinnati have 53-degree countersunk holes at 8” centers. They are perfect for cutting mild and stainless steel with up to half the cutting power. This blade is extremely durable and can be used in a wide range of cutting applications. These blades come in a variety of sizes and are made by a fifth-generation family business.

Shock grade steel

The right metal shear knives will make your metal-cutting machine more productive. There are many types of steel shear knives on the market. However, shock grade steel is the most widely used. It is suitable for cutting mild and stainless steels up to 1″ thick. It can be used in as little as 50% of your machine’s power, making it suitable for cutting stainless-steel.

Hardened slideways

The benefits of hardened slidesways have been known by shear knife manufacturers for years. Through a variety of techniques, they have made their products stronger and more durable. Carbonizing, carburizing and nitriding are some of the hardening methods. Another process is to regrind the slideway’s ends 65. This ensures that it lasts longer and maintains its accuracy. Here https://www.kangblade.com/ is a brief description of the main benefits of hardened slideways for shear knives.

Hydraulic demolition shear blades

A hydraulic demolition scrap shear is a great way to reduce costs and increase production. The versatile machine can be used to demolish and recycle scrap metal all over the globe. Its advanced design and jaws allow for productivity improvements. You can also change the blades easily, which reduces downtime. Hydraulic demolition scrap saws are capable of handling a wide range of materials including wood, cardboard and roofing shingles. These materials can be transformed into value-added products with the right blades.